Innovative Strength & Smart Solutions

in Thermal Management for Motor Vehicles

Innovative & individual thermal management solutions in the automotive sector.

At Innerio Heat Exchanger, innovation means setting ambitious goals and consistently implementing new solutions in time for our customers. State-of-the-art tools for perfect execution are the prerequisite. Both we and our products are flexible & high-performance with consistent quality.

Individual

Thermal management solutions for individual customer needs.

- We analyse the specific customer requirements in terms of installation space, performance or weight and develop individual solutions. If desired, we can provide support in the coordination of the specifications in advance.

- Engineering know-how and hands-on spirit help us solve challenges for our customers.

High-performance

Highest product performance with lowest component weight.

- We stand for high-performance thermal management solutions based on patented origami technologies and customized coordinated designs.

- By using less material, the products become lighter and thus contribute directly to the reduction of avoidable emissions.

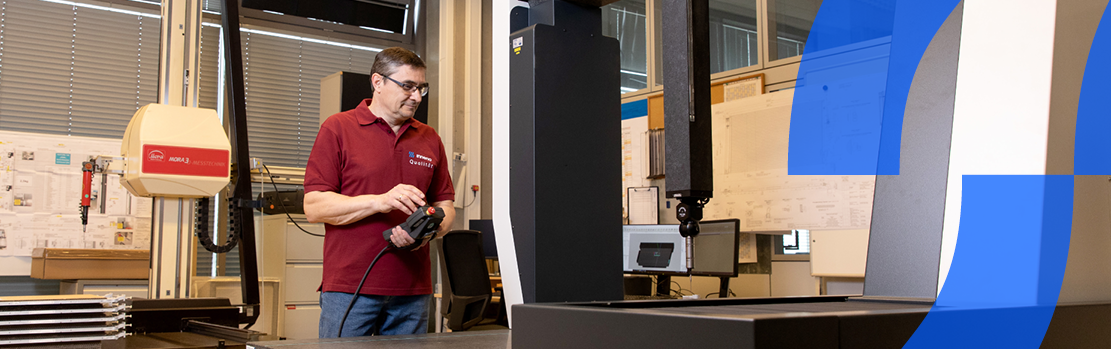

Reliable

Reliability of the products and reliability as a partner.

- “100% checked” means that every product is inspected and tested for conformity.

- The patented material technology guarantees the best corrosion properties & resistance to environmental influences.

- “Zero Defects” stands for certified processes that ensure consistent reliability.

Innovative Strength & Product Development

Consistent Development Projects

We understand our customers and deliver today the right answers for the future. The enormous demands on the vehicle industry and the transformation of drive types make us strive for innovative, flexible solutions for thermal systems.

This means transparent development planning accompanied by simulation, feedback loops and customer interaction.

More than 50 patents are the best proof of our innovative strength.

Origami Technologie

at Innerio

Origami – that means top performance: aluminium strips in the micrometre thickness range are brought together in three layers at 100m per minute and then join together in the core of the heat exchanger to form refrigerant-carrying pipeline systems. This is origami and this is what we master with our patented technologies and processes.

The advantages: Low weight, high heat transfer performance and minimised risk of corrosion.

15 % of all motor vehicles in Europe are equipped with Innerio’s origami condensers.

Dynamic

Development Team

A team with unique experience, knowledge and no end of enthusiasm! In our innovative environment, we enable the optimal merging of ideas into products from a single mould.

We want to impress with customer satisfaction: Both at the start of production of the new solutions, as well as with the overall service life of our products.

Innovation is our goal – and we are happy to go the “extra mile” to achieve it.

Prototyping

in the Innovation Lab

From the idea to the first tangible products – in maximum variants and without limits:

Thanks to our in-house prototype construction and the Innovation Lab, prototypes can be built within a short time and initial findings can be validated on them. This enables short development loops and rapid adaptation of any specifications, even before costly tools and fixtures have to be obtained.

Quicker and more efficiently to optimised solutions through prototyping.

From the design concept to the series product

Analysis

Concept

Design

Prototype

Validation

Production

Analysis

Concept

Design

Prototype

Validation

Production

Innerio’s Development Process:

- Requirements analysis by our experts based on customer needs.

- Development of a product and solution concept. Individual adaptations together with the customers.

- System development in which the requirements are translated into tangible products.

- In-house prototyping allows the developed solutions to be manufactured already at a very early stage.

- Design and process validation with support of the customer throughout our project management up to series production readiness and beyond

Individual Solutions

Innerio Heat Exchanger is your flexible, reliable partner for individual, innovative thermal management solutions.

We also find efficient solutions for your special thermal management requirements for all vehicles. Simply get in touch with us!